Rolled steel roof, regarded as the „Mercedes among tin roofs“, is the best choice for roofs subject to heritage conservation requirements or with very low angles of inclination. The timeless double welt roofing proven over the centuries requires an experienced roofer, but is suitable virtually for any roofs with inclination over 5 degrees. Scandinavian roofing manufacturers have created a visually similar product – namely, a profiled sheet with concealed fastening – to grant the same timeless look to tens of thousands of new or renovated Estonian homes.

Rolled steel roof, regarded as the „Mercedes among tin roofs“, is the best choice for roofs subject to heritage conservation requirements or with very low angles of inclination. The timeless double welt roofing proven over the centuries requires an experienced roofer, but is suitable virtually for any roofs with inclination over 5 degrees. Scandinavian roofing manufacturers have created a visually similar product – namely, a profiled sheet with concealed fastening – to grant the same timeless look to tens of thousands of new or renovated Estonian homes.

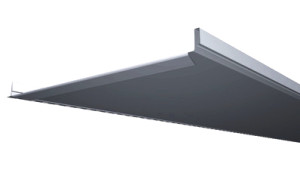

Classic is an ideal choice for a sloping roof with decent inclination (preferably from 15 degrees) and relatively few protruding elements or obstructions accumulating snow. Because of this, Classic is an excellent choice for residential areas with new buildings, where Scandinavian and ascetic architecture prevails.

In contrast to rolled sheet, Classic allows achievement of a relatively smooth and neat result pleasing to the eye. Nevertheless, for successful implementation of this modest and logical expectation, a master roofer’s skills and proper materials are required. Similarly to other tin roofs, the battens and underlay supporting the Classic must be approximately level. If a batten is installed lower or higher than the rest, this results in a depression or bulge in the installation of roofing panels, respectively. This has no effect on the watertightness or service life of the roof, but offends the eye. Also, in case of Classic, coatings with matte surface treatment should be preferred, as they will “smooth out” quite a few ripples. Classic panels have pre-treated oblong screw holes at the edges, which allow controlled shifting of the long sheet on the roof to compensate for thermal expansion. However, in hot summer weather, some sheet metal rippling is unavoidable – after all, metal is a living material. To avoid rippling, the eaves-facing edges of sheet metal panels are not fixed rigidly with penetrating screws, but are bent around the eaves flashing similarly to rolled sheet. This ensures screw-free eaves that are also straight and resistant to gusts of wind. The modern Classic comes with the eaves edge pre-bent at the factory; you only need to press it shut around the eaves flashing in the course of installation.

In contrast to rolled sheet, Classic allows achievement of a relatively smooth and neat result pleasing to the eye. Nevertheless, for successful implementation of this modest and logical expectation, a master roofer’s skills and proper materials are required. Similarly to other tin roofs, the battens and underlay supporting the Classic must be approximately level. If a batten is installed lower or higher than the rest, this results in a depression or bulge in the installation of roofing panels, respectively. This has no effect on the watertightness or service life of the roof, but offends the eye. Also, in case of Classic, coatings with matte surface treatment should be preferred, as they will “smooth out” quite a few ripples. Classic panels have pre-treated oblong screw holes at the edges, which allow controlled shifting of the long sheet on the roof to compensate for thermal expansion. However, in hot summer weather, some sheet metal rippling is unavoidable – after all, metal is a living material. To avoid rippling, the eaves-facing edges of sheet metal panels are not fixed rigidly with penetrating screws, but are bent around the eaves flashing similarly to rolled sheet. This ensures screw-free eaves that are also straight and resistant to gusts of wind. The modern Classic comes with the eaves edge pre-bent at the factory; you only need to press it shut around the eaves flashing in the course of installation.

An advantage of Classic is the ridge joint characterised by good openness – by the way, it is used increasingly often in classic rolled sheet roofs as well. Use of acoustic insulation under Classic is a must (and also highly recommended under rolled sheet roof), as it restrains the decibels of the vibrating sound generated by the panels in stormy weather. It should be noted that Classic is not a perfect twin of rolled sheet, especially as regards covering roofs of very low inclination. The steel used for producing Classic must be at least 0.50mm thick and rigid enough for the metal to “play” upon thermal expansion. Durability and long service life are ensured by standard or even better paint and zinc coating layers on the material. Consult with an experienced master roofer capable of providing qualified advice on the suitability of Classic for your home.

An advantage of Classic is the ridge joint characterised by good openness – by the way, it is used increasingly often in classic rolled sheet roofs as well. Use of acoustic insulation under Classic is a must (and also highly recommended under rolled sheet roof), as it restrains the decibels of the vibrating sound generated by the panels in stormy weather. It should be noted that Classic is not a perfect twin of rolled sheet, especially as regards covering roofs of very low inclination. The steel used for producing Classic must be at least 0.50mm thick and rigid enough for the metal to “play” upon thermal expansion. Durability and long service life are ensured by standard or even better paint and zinc coating layers on the material. Consult with an experienced master roofer capable of providing qualified advice on the suitability of Classic for your home.

Source: Steelroof Plekikoda OÜ / AS Toode